Emergency Preparedness: Protocols for Handling Accidents Involving Dangerous Goods Boxes

As the old adage goes, it’s always better to be safe than sorry. This holds particularly true for those managing, handling, or responding to accidents involving dangerous goods boxes. The safety of individuals and the environment hinges on robust protocols that are ingrained in the procedures and reactions to such emergencies.

For safety professionals, warehouse managers, and first responders, understanding and implementing these protocols is a critical facet of their day-to-day responsibilities. Here are eight essential steps to bolster your emergency preparedness for incidents involving dangerous goods boxes.

Understanding Dangerous Goods Boxes

● Definition and Types

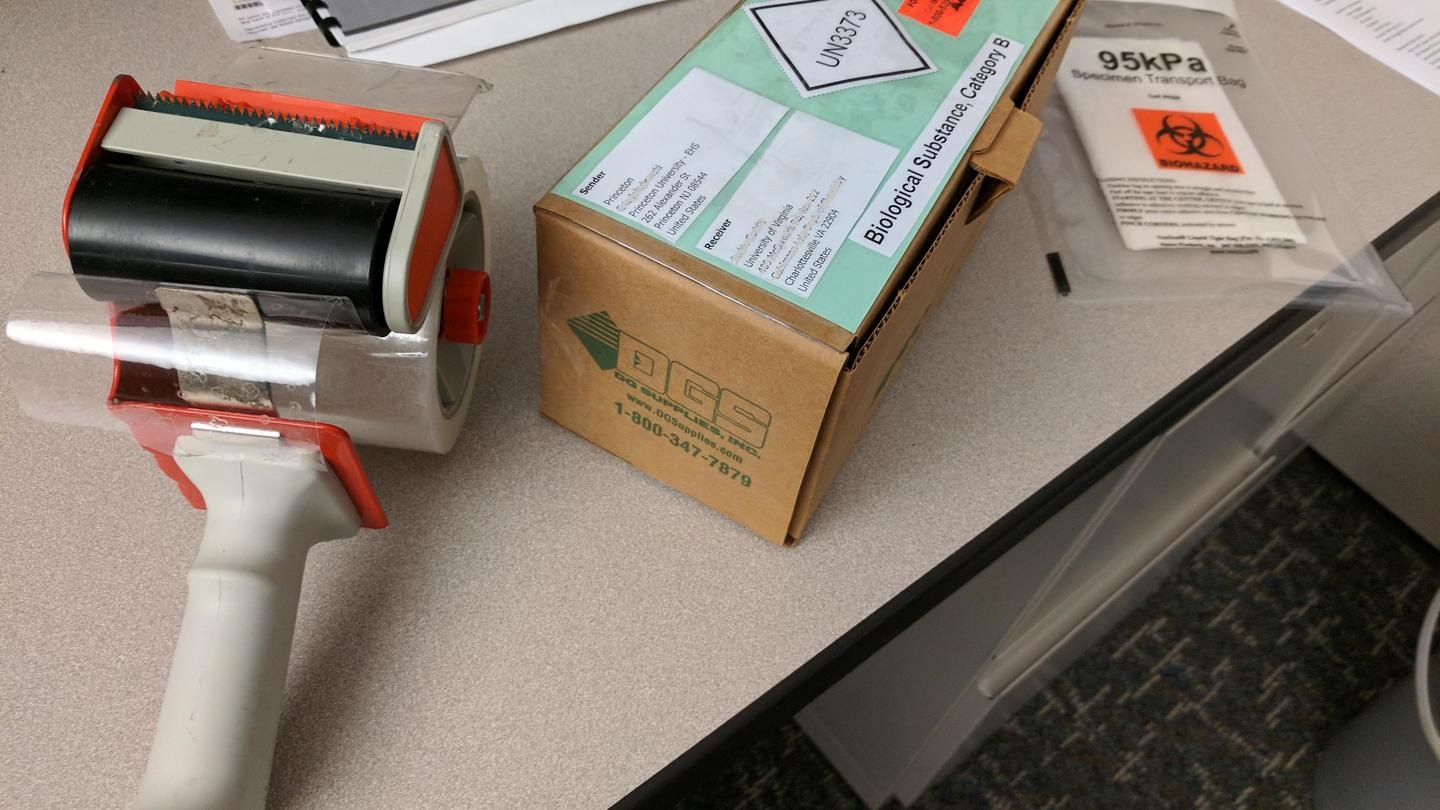

Dangerous goods boxes are specialized containers designed to store and transport hazardous materials safely. These can range from small, portable kits to large, ship-mounted containers capable of holding substantial volumes of dangerous goods.

● Common Hazardous Materials

Materials commonly kept in dangerous goods boxes include corrosives like acids, flammables such as fuels and solvents, and a variety of toxic and infectious substances. Understanding the specific risks associated with each type of material is crucial for effective emergency handling.

Risk Assessment and Planning

● Conducting a Thorough Risk Assessment

A site-specific risk assessment involves evaluating the types and quantities of dangerous goods, potential accident scenarios, the presence of ignition sources, and the proximity of hazards to personnel and critical infrastructure.

● Developing an Emergency Response Plan

The response plan should be a dynamic document that outlines specific actions to take in different types of incidents involving dangerous goods boxes. It should also include an evacuation plan for the site and regular drills to ensure preparedness.

Training and Education

● Comprehensive Employee Training

Employees must receive comprehensive and ongoing training to ensure they are familiar with the properties of dangerous goods boxes, proper handling procedures, and the use of personal protective equipment (PPE).

● Educating First Responders

It’s imperative to regularly coordinate with local emergency services to familiarize them with the layout of the site, the locations of dangerous goods boxes, and the specifics of the emergency response plan.

Safety Equipment and Tools

● Essentials You Cannot Do Without

The indispensable safety equipment for handling dangerous goods boxes includes spill kits, containment supplies, eye and skin protection, and respiratory equipment for toxic fume situations.

● Maintenance and Inspection

Regular maintenance and inspection of safety equipment are non-negotiable. This ensures that equipment is in good working order when needed and avoids any unpleasant surprises in emergencies.

Incident Response and Communication

● Immediate Response Actions

In the event of a spill or leakage from a dangerous goods box, the immediate response involves containing the spread of the material, isolating the area, and activating the emergency response procedures.

● Effective Communication

Articulate and timely communication with all involved parties is critical. This includes staff, management, emergency services, and regulatory authorities. Clear information reduces the risk of misunderstandings and accelerates the appropriate response actions.

Post-Incident Evaluation and Lessons Learned

● Conducting a Thorough Investigation

An investigation aims to establish the root cause of the incident. This may involve reviewing video footage, examining equipment, and interviewing personnel.

● Implementing Corrective Actions

Based on the findings of the investigation, a set of corrective actions should be developed to address any lapses in protocols or safety measures that led to the incident.

● Sharing Lessons Learned

The learning from incidents must be shared across the organization and with other stakeholders, potentially sparing others from similar situations. Conducting workshops, updating policies, and revising training materials are avenues to disseminate these critical lessons.

Conclusion

In logistics, the reality is that prevention often falls short, and it is the bread and butter of preparedness — the protocols, equipment, and most importantly, the people who are well-trained and educated — that see us through grim situations.

Adhering to the right protocols in the handling of dangerous goods boxes does more than ensure compliance; it is the bedrock of a robust safety program that protects personnel, the environment, and the public.