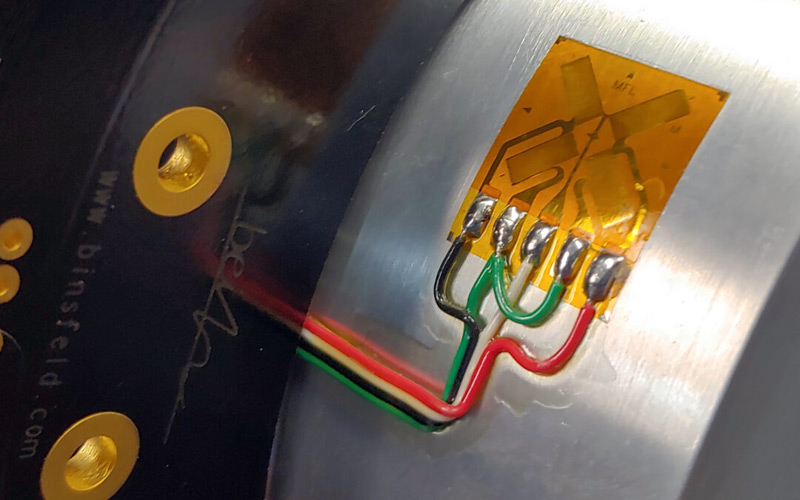

Strain Gauges Provide Accurate Measurements for Reliable Engineering and Testing

Accurate measurements are crucial in engineering, research, and manufacturing to ensure safety and efficiency. Strain gauges help measure forces, deformations, and stresses in various materials and structures. They play an important role in testing, data acquisition, automation, and quality assurance. These sensitive sensors detect even the smallest changes, making them essential in industries like aerospace, construction, and automotive. Engineers and researchers rely on strain gauges to analyze material behavior, improve product performance, and enhance durability. Their precise measurements help prevent failures and ensure high-quality standards in different applications.

Below are five important ways strain gauges are used in different applications.

Structural testing and safety

Strain gauges are widely used in construction and civil engineering. They help measure stress in bridges, buildings, and other structures. Engineers use this data to detect potential weaknesses and prevent failures. By monitoring strain over time, they can ensure that structures remain strong and safe under different conditions.

Automotive and aerospace applications

In the automotive and aerospace industries, strain gauges test the durability of vehicles, aircraft, and their components. They measure how different materials react to forces such as acceleration, vibration, and pressure. This ensures that parts can withstand real-world conditions. The data collected helps in designing safer and more efficient vehicles and aircraft.

Manufacturing and quality assurance

Manufacturers use strain gauges to improve product quality and performance. They test how materials and components respond to different forces before mass production. This helps identify defects and weaknesses early in the process. Quality assurance teams use strain gauge data to ensure that products meet safety and performance standards before reaching the market.

Medical equipment and biomechanics

Strain gauges are used in the medical field to develop and test advanced equipment. They help in measuring forces in prosthetics, implants, and rehabilitation devices. Scientists also use them in biomechanics research to study body movements and muscle performance. This data helps improve medical treatments and assistive devices.

Industrial automation and robotics

In automation and robotics, strain gauges measure force and stress in mechanical parts. They help monitor loads on robotic arms, conveyor belts, and industrial machines. This ensures that machines operate efficiently and safely. By detecting strain in real time, strain gauges help prevent mechanical failures and improve productivity.

Final thoughts

Strain gauges are essential for accurate measurements in various industries. They help engineers, scientists, and manufacturers improve safety, performance, and efficiency. Whether in construction, aerospace, medicine, or automation, these sensors play a crucial role in ensuring reliable and high-quality results.