What to Look for in a System Integration Partner for Warehouse Growth

As warehouses face increasing pressure to move faster, scale smarter, and operate with greater precision, system integration has become essential. It’s not just about adding technology—it’s about making sure everything works together seamlessly, from your warehouse management system to your automated equipment.

But choosing the right system integration partner can be just as important as the technology itself. A well-matched partner doesn’t just install software or machines—they become a strategic collaborator in building an efficient, future-ready warehouse.

Here’s what to look for when selecting a system integration partner that can support—and accelerate—your warehouse growth.

Understand when you need a system integrator

If your warehouse is adding automation, upgrading legacy systems, or facing growing operational complexity, chances are you need a system integrator. This is especially true if:

- Your WMS, ERP, and automation tools don’t “talk” to each other

- You’re expanding operations across multiple sites

- You’re planning to add robotics, AGVs, or AS/RS systems

- Manual processes are causing delays or errors

- You’re investing in a broader warehouse automation strategy

The right partner helps you assess where you are, where you’re headed, and how to connect the dots in between.

Look for deep technical expertise and a tailored approach

Every warehouse is different—and your integration strategy should reflect that. Avoid partners who offer one-size-fits-all packages. Instead, look for warehouse automation companies that take the time to understand your facility layout, order profiles, SKU volume, and team workflows.

Ask about:

- Experience with similar warehouse environments (e.g., retail, cold storage, high-volume eCommerce)

- Specific technologies they’ve integrated successfully (conveyors, robotics, voice picking, etc.)

- How they customize integration based on space, throughput, and growth goals

- How they test and simulate system performance before rollout

A strong integrator knows how to balance standardization with flexibility—delivering solutions that are robust but not rigid.

Prioritize partners with proven warehouse automation experience

While some integrators focus on software or enterprise systems, those with direct warehouse automation experience bring additional value. They understand how physical systems behave, how automation impacts workflows, and how to design solutions that work at scale.

Top warehouse automation companies often provide end-to-end integration services, including:

- Equipment selection and layout planning

- WMS integration and data synchronization

- Installation and testing of automation components

- System optimization and performance analytics

- Ongoing support and service

Working with a provider that understands both the digital and physical layers of your operation ensures fewer disconnects—and better long-term results.

Evaluate their integration methodology

Integration isn’t just a task—it’s a process. The best partners follow a structured, collaborative approach that reduces risk and delivers better outcomes.

Look for a partner who can clearly walk you through their project phases, including:

- Discovery: Site visits, data gathering, process mapping

- Design: Solution architecture, technology selection, layout modeling

- Simulation: Virtual modeling to validate system performance

- Implementation: Coordinated installation and testing

- Training & Change Management: Preparing your team for the transition

- Support: Ongoing maintenance, monitoring, and future upgrades

Ask how they manage timelines, milestones, and cross-team communication. A strong methodology leads to smoother execution and fewer surprises.

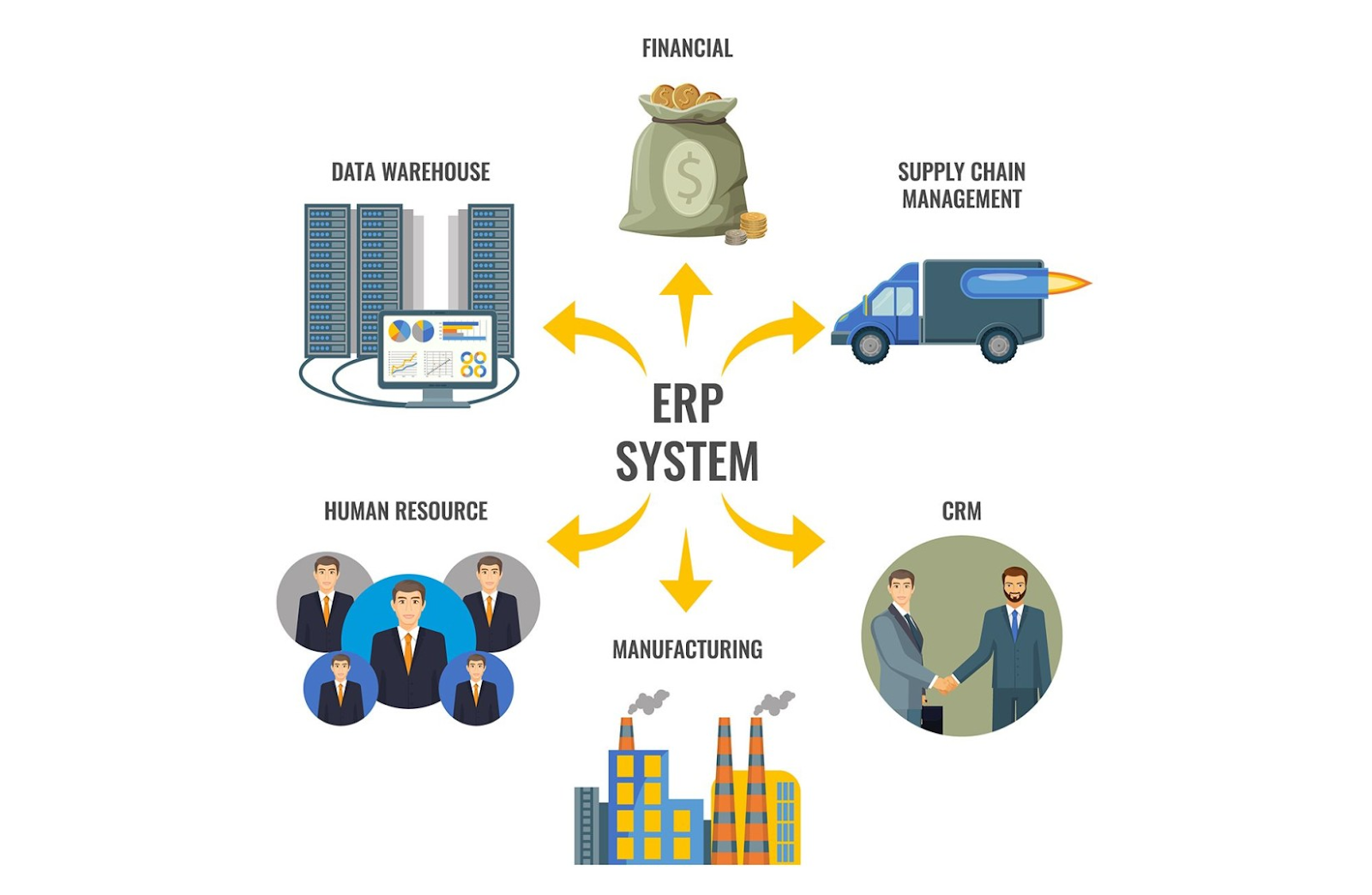

Make sure they can integrate with your current systems

Your WMS, ERP, TMS, and other software systems aren’t going away anytime soon. Your integration partner should be well-versed in connecting legacy platforms with new technologies—so everything works as one cohesive ecosystem.

Whether you’re running SAP, Manhattan, NetSuite, or a proprietary WMS, your integrator should understand:

- API integration and middleware solutions

- Data flow optimization and real-time sync

- User experience and interface consistency

- Custom dashboards and reporting tools

If they’ve worked with your systems (or similar ones) before, that’s a major plus. Seamless data flow is the foundation of warehouse automation—and your partner should be fluent in making it happen.

Check their scalability and long-term support

A good integration partner isn’t just there for go-live—they’re with you as your operation grows. Ask about:

- How their systems scale (new zones, higher volumes, more SKUs)

- Upgrade paths and modular automation options

- Maintenance programs and remote support services

- Their ability to adapt to new technologies (like AI or machine learning)

- How they stay current with warehouse automation trends

Growth requires agility, and your integration partner should be equipped to evolve with you—not lock you into a system that can’t adapt.

Ask for references and real-world results

Reputation matters. Before committing, ask for client references—especially from similar industries or warehouse sizes. Look for testimonials or case studies that speak to:

- On-time project delivery

- Tangible improvements in efficiency or accuracy

- Responsiveness during implementation

- Quality of training and ongoing support

- Return on investment (ROI) within 6–18 months

Don’t just take their word for it. See how they’ve performed in real-world warehouse environments.

Your growth depends on the right connections

As warehouse operations become more automated and data-driven, integration becomes the backbone of success. Choosing the right system integration partner isn’t just about compatibility—it’s about trust, expertise, and a shared commitment to long-term growth.

The most successful warehouses don’t just invest in equipment—they invest in relationships with warehouse automation companies that understand their challenges, build custom-fit solutions, and stay in the loop as the business evolves.

Because growth doesn’t happen in silos. It happens when your systems—and your people—work better together.